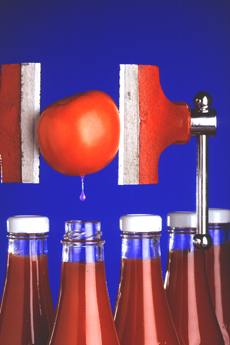

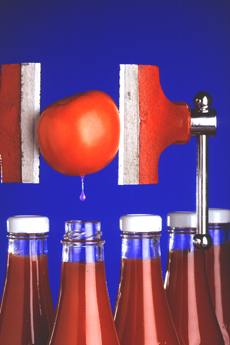

All ketchups are hardly created equal, as you’ll see in our review of 42 different brands. Photo © Claudio Beldini |Fotolia.

|

STEPHANIE ZONIS is a Contributing Editor at THE NIBBLE.

|

|

October 2007

Updated November 2008

|

|

A Fresh Look At Ketchup

Page 3: How Ketchup Is Manufactured

This is Page 3 of a nine-page article. Click on the black links below to visit other pages.

How Ketchup Is Manufactured

Large-scale ketchup making begins with the selection of tomatoes. Enotes.com asserts that only tomatoes superior in color, flavor, texture and yield are used. Consistency is of great importance, too, as consumers want their ketchup to be the same, bottle after bottle. Tomatoes are harvested mechanically, graded, sorted, washed and chopped. They’re precooked in stainless steel vats, a process called “scaling,” which preserves them and eliminates any bacteria.

- Machines called cyclones separate the precooked tomato pulp from any stems, seeds or skins. The pulp is screen-filtered; some portion of it is usually saved for use after the harvest is over.

The filtered pulp is pumped into cooking vessels and heated to boiling. While it cooks, a process that takes some 30 to 45 minutes, sweetener, vinegar, spices, salt and flavorings are added in exact quantities. When these ingredients are added often depends upon their form. Enotes.com states that “most spices are added early in the cooking process,” but if spice oils are used instead of actual spices, these “volatile” oils must be added later in the process. Sugar and salt can be added at any time, but if sugar is added later, it’s less likely to burn. The cooking mixture is kept moving by mechanical stirring blades. The cooking temperature is monitored carefully; too high a temperature will result in an overcooked, flat-tasting product. The filtered pulp is pumped into cooking vessels and heated to boiling. While it cooks, a process that takes some 30 to 45 minutes, sweetener, vinegar, spices, salt and flavorings are added in exact quantities. When these ingredients are added often depends upon their form. Enotes.com states that “most spices are added early in the cooking process,” but if spice oils are used instead of actual spices, these “volatile” oils must be added later in the process. Sugar and salt can be added at any time, but if sugar is added later, it’s less likely to burn. The cooking mixture is kept moving by mechanical stirring blades. The cooking temperature is monitored carefully; too high a temperature will result in an overcooked, flat-tasting product.

Photo by Scott Bauer, courtesy of U.S. Agricultural Research Service.- Once the cooking process is complete, the ketchup is again filtered, creating a smoother consistency. Any excess air is removed from the ketchup, as it might allow for darkening of the product or the growth of bacteria. The ketchup is pumped into a filling machine at a temperature of 190°F or higher (again, to avoid any bacterial contamination). Bottles or other containers are filled and sealed immediately.

- The sealed containers must be cooled to prevent a condition called “stack burning,” which occurs if ketchup remains at high temperatures for too long after the cooking process is finished. Cold air or cold water provide a chilly environment in which the temperature of the ketchup can safely decrease.

Continue To Page 4: Ketchup Today

Go To The Article Index Above

|

The filtered pulp is pumped into cooking vessels and heated to boiling. While it cooks, a process that takes some 30 to 45 minutes, sweetener, vinegar, spices, salt and flavorings are added in exact quantities. When these ingredients are added often depends upon their form. Enotes.com states that “most spices are added early in the cooking process,” but if spice oils are used instead of actual spices, these “volatile” oils must be added later in the process. Sugar and salt can be added at any time, but if sugar is added later, it’s less likely to burn. The cooking mixture is kept moving by mechanical stirring blades. The cooking temperature is monitored carefully; too high a temperature will result in an overcooked, flat-tasting product.

The filtered pulp is pumped into cooking vessels and heated to boiling. While it cooks, a process that takes some 30 to 45 minutes, sweetener, vinegar, spices, salt and flavorings are added in exact quantities. When these ingredients are added often depends upon their form. Enotes.com states that “most spices are added early in the cooking process,” but if spice oils are used instead of actual spices, these “volatile” oils must be added later in the process. Sugar and salt can be added at any time, but if sugar is added later, it’s less likely to burn. The cooking mixture is kept moving by mechanical stirring blades. The cooking temperature is monitored carefully; too high a temperature will result in an overcooked, flat-tasting product.